Where Tactical Engineering Meets Human-Centered Thinking

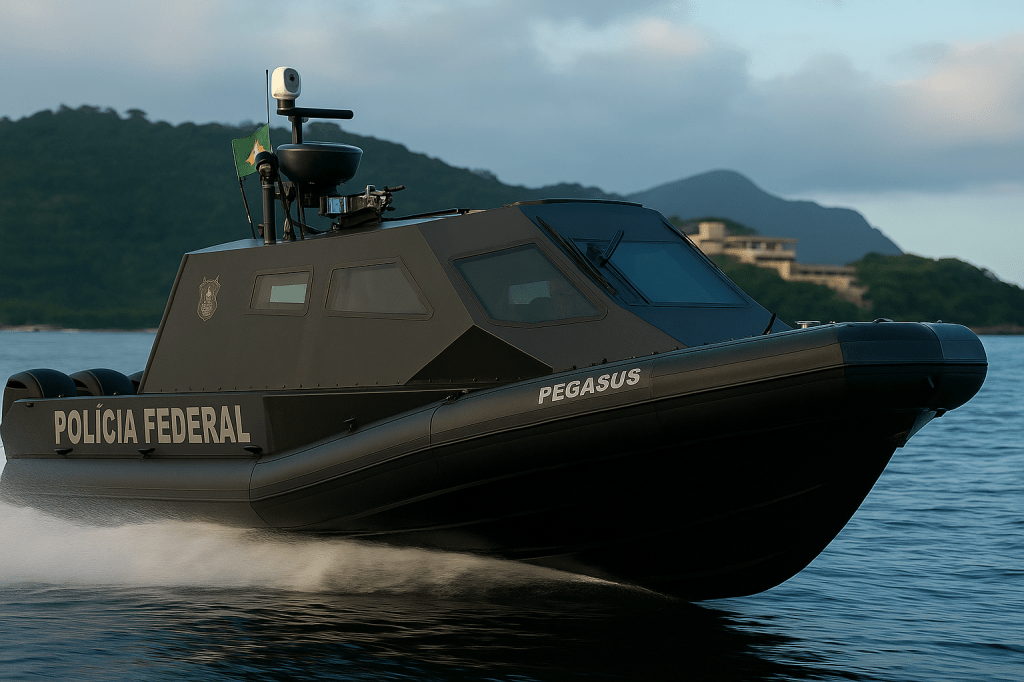

In 2012, while working as a designer at DGS Defense (Rio de Janeiro, Brazil), the country’s pioneer in HDPE naval construction. Our team won a national tender to develop a next-generation attack interceptor for the Brazilian Federal Police. The brief was uncompromising: a stealth-shaped, armored cabin vessel with high speed and precise maneuverability, capable of operating on the demanding rivers of the Brazil–Argentina–Paraguay tri-border.

I served as the lead for design, usability, and operational workflow, translating mission reality into a cockpit and cabin that performed under pressure. Working hand-in-hand with Project Manager Ricardo Ermel and our production teams: welders, electricians, fitters, and painters. We turned a complex set of constraints into a coherent system: a patented low-RCS armored cabin, an HDPE hull engineered for impact tolerance and low maintenance, and an interior optimized for clear visibility, intuitive reach, and rapid role transitions (pilot ↔ navigator ↔ shooter) at speed.

This project marked a turning point for DGS: it combined stealth geometry, survivability, and human-centered design in a single platform—purpose-built for riverine pursuit, interdiction, and long-range patrol, and crafted with the realities of fabrication and field service in mind.

🚤DGS 888 Cabin – Tactical Stealth with Human Protection at the Core

At the heart of the DGS 888 Pegasus lies a patented, armored cabin designed for tactical combat operations, combining stealth technology, ballistic resistance, and ergonomic comfort in a single cohesive structure.

Inspired by stealth architecture used in military aviation, the cabin was engineered with angular surfaces and sloped geometry to deflect radar waves, dramatically reducing its radar signature and improving mission concealment. This geometric design isn’t just for aesthetics, it’s a functional shield against early detection.

Internally, the cabin is optimized to host up to 6 Federal Police agents, distributed as follows:

- 🧭 1 pilot, with complete visibility and access to intuitive controls

- 🔫 1 shooter, seated in a foldable tactical seat with direct access to a top hatch that leads to a mounted MAG machine gun support system

- 👥 4 additional seats for tactical team members, with shock-absorbing bases and secure restraints

The entire structure is protected with NEB Level 3 ballistic shielding, capable of resisting .30 and .60 caliber rounds, providing reliable protection in active combat zones.

Despite its military-grade specifications, the cabin was carefully designed with ergonomics, spatial flow, and comfort in mind. Every element, from seat layout to hatch access, was shaped to reduce fatigue, support decision-making under pressure, and preserve agent safety in high-speed, high-risk scenarios.

Just like in UX/UI design, the focus was on user needs in critical environments:

- Clear spatial hierarchy and task flow

- Seamless access to mission-critical tools

- Safety through structure

- Efficiency through layout

This cabin is not just a protective shell, it’s a human-centered command unit on water.

🎯Design Objective

Goal:

Develop a stealth, armored, and ergonomic cabin for high-speed tactical operations in border zones, minimizing radar visibility and maximizing crew safety and performance.

Constraints:

- Stealth detection suppression (minimized RCS)

- Ballistic protection (NEB III)

- Accommodate 6 agents

- Navigation visibility and tactical functionality

- Marine-grade material constraints (HDPE, aluminum)

📑Benchmark Research

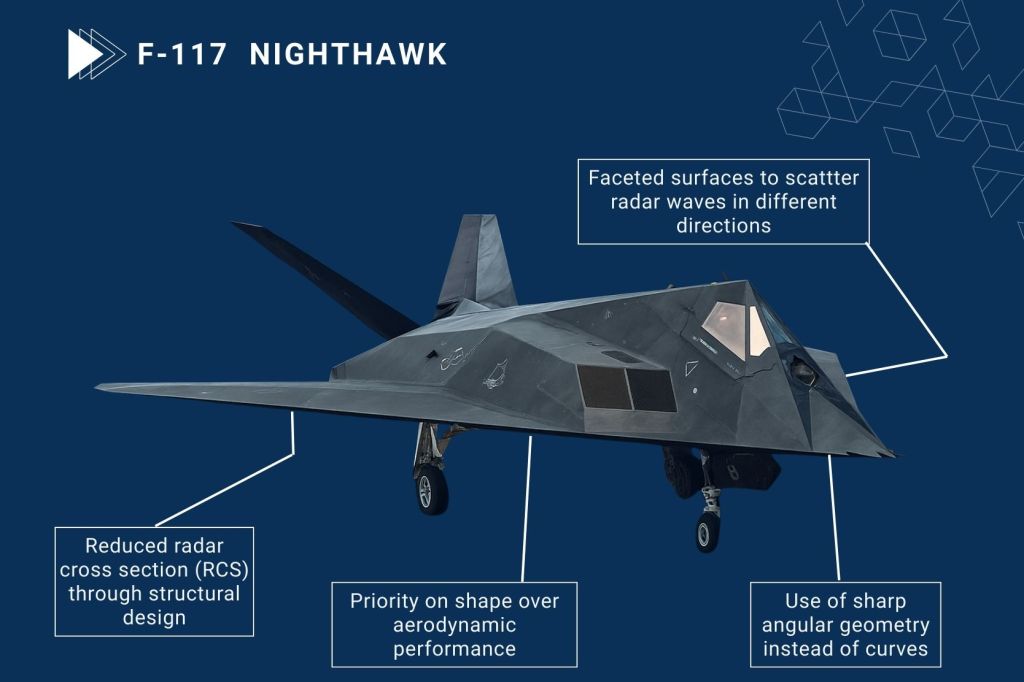

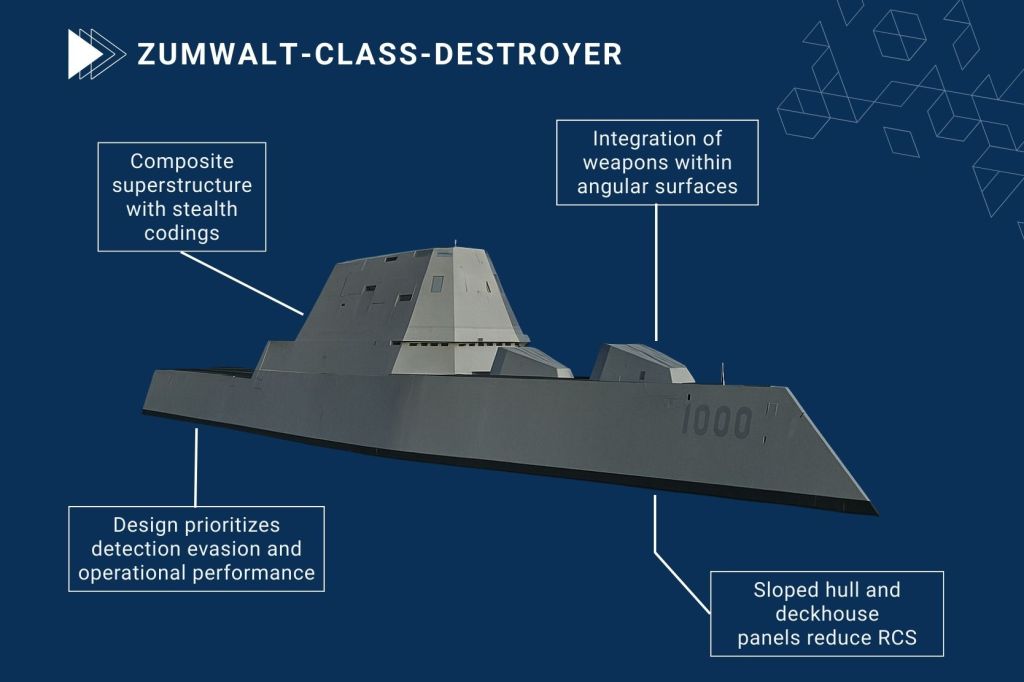

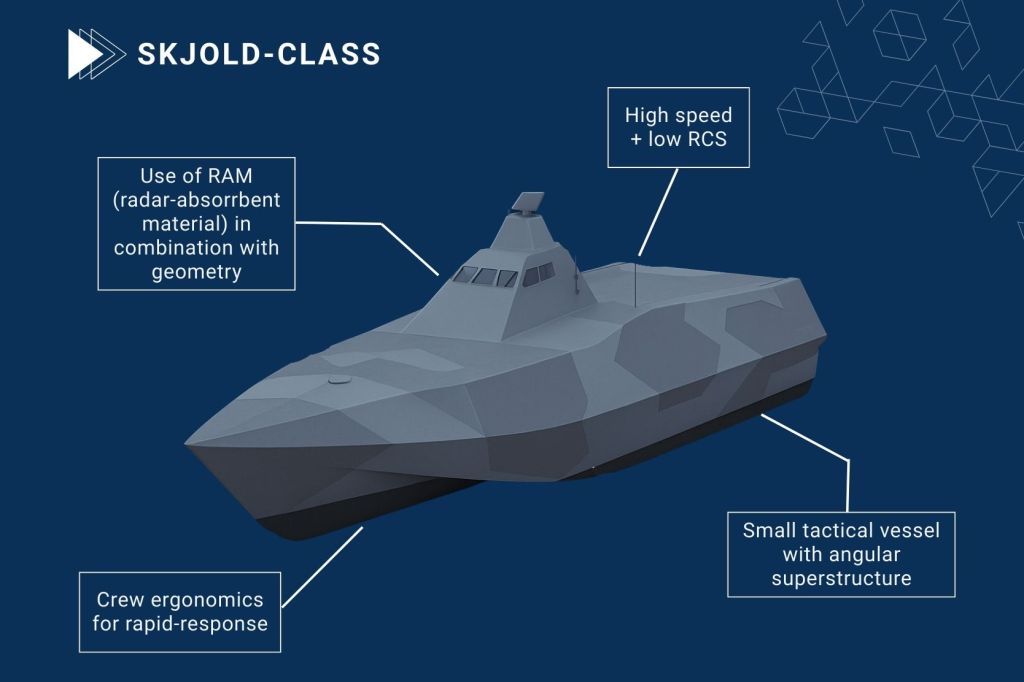

Before diving into any design sketch or CAD model, we knew we had to look around. In this benchmark phase, we explored some of the most advanced tactical vehicles and vessels in the world, from the iconic F-117 Nighthawk, to stealth warships like the Zumwalt-Class and Skjold-Class.

But this wasn’t just about aesthetics or cool shapes. It was about understanding how form follows function when stealth, protection, and usability are non-negotiable. As UX designers, we’re not just designing “how it looks”, we’re designing how it works.

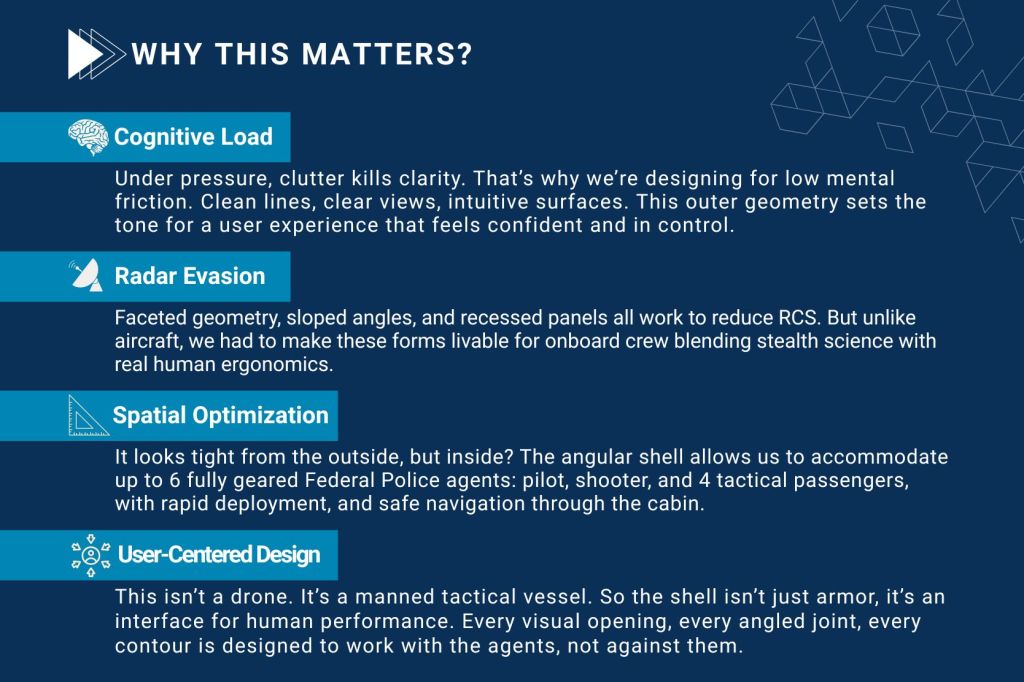

We focused on:

- Radar evasion: studying angular geometries, radar-absorbent materials, and edge treatment used in military applications;

- User-centered design: mapping crew positions, visibility lines, access zones, and emergency egress, always keeping our six federal agents in mind;

- Spatial optimization: testing seating layouts, modular setups, and how movement flows inside a compact, armored space;

- Cognitive load: analyzing how interface clutter, poor sightlines or bad posture can lead to operational delays or decision fatigue.

Benchmarking wasn’t just a checkmark on our process, it grounded our vision. It helped us find the balance between survivability, usability, and performance, and ensured our final design would not only protect, but empower the agents inside it.

🔷 Aviation Reference

🔷 Naval Reference

🔷 Fast Attack Craft Reference

💡Insights from Benchmarking

- Angle > Curves: Stealth relies more on surface inclination than on coatings

- Layered utility: Form must serve stealth, protection, and usability simultaneously

- Vertical is visible: Upright panels (perpendicular to waterline) bounce signals back to radar

- Ergonomics matter: Visibility and movement pathways must be designed without compromising stealth

Qualitative Research

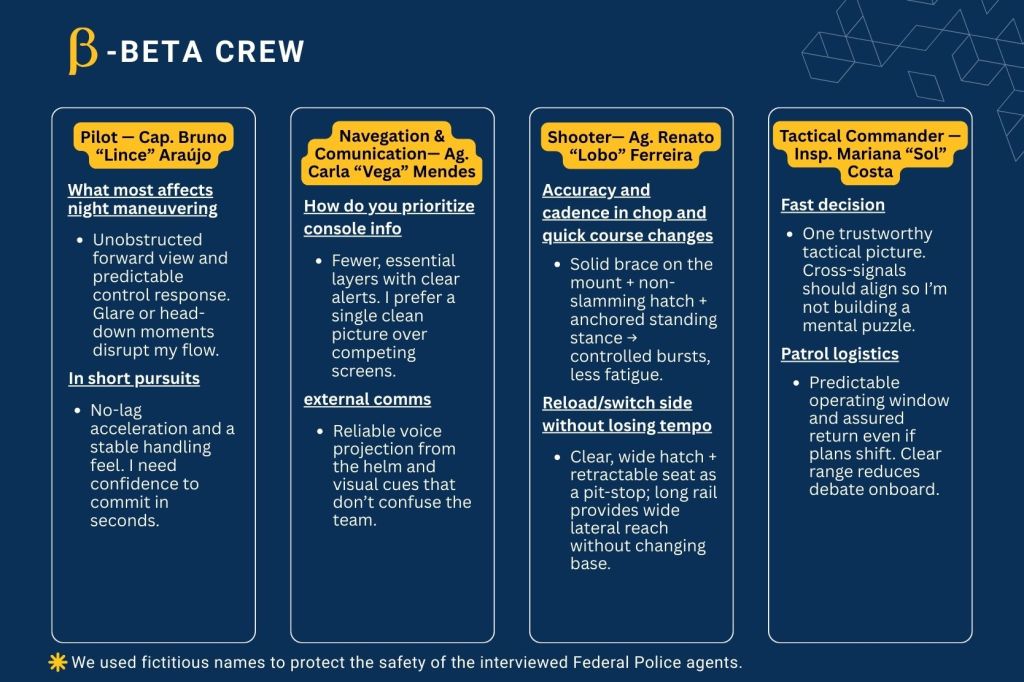

We conducted qualitative interviews with two tactical border crews—Alpha and Beta—each composed of a Pilot, Navigator & Communications, shooter, and a Tactical Commander. These teams operate on the rivers of the Brazil–Paraguay–Argentina tri-border under high stress, low light, debris, and strong current.

The conversations broadened our field of view and helped us translate on-river realities into design criteria. From these interviews, we mapped the crews’ needs into clear requirements for the cabin, systems, and mission workflow:

🧪Concept Cabin Prototyping

After a deep dive into stealth-forward benchmarks—from the angular airframe of the F-117 Nighthawk to the radical hull geometry of the Zumwalt-class—we paired those references with what the Alpha and Beta field teams told us on the river. Pilots asked for eyes-up flying with broad sightlines and less glare/spray. Shooters wanted fast, safe transitions from seat to rooftop without snagging gear. Command and sensors operators pushed for low cognitive load and quiet signatures. All of them emphasized crew protection without sacrificing movement paths inside the cabin.

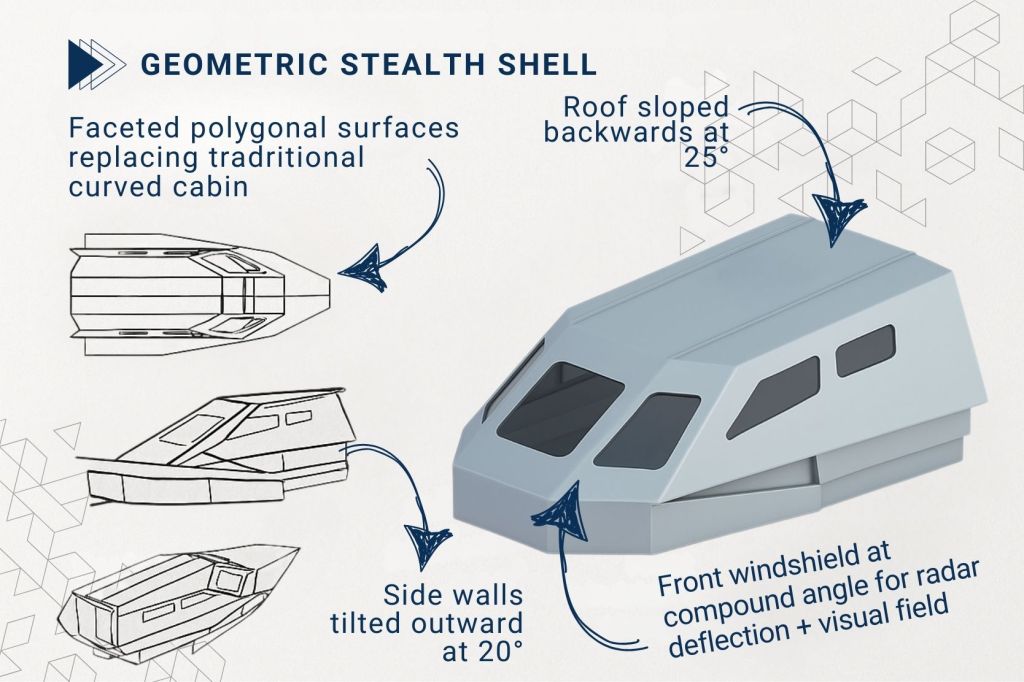

The first phase of concept prototyping focused on the outer geometry of the cabin—what we’re calling the Geometric Stealth Shell. This isn’t just a visual style; it’s the physical handshake between stealth physics and human factors. Every facet, slope, and edge was shaped to shed radar energy, preserve pilot visibility, and let operators move quickly under armor. In short: hide from sensors, protect the team, and keep the interface—the cabin itself—usable under high-stress, low-light, high-spray scenarios.

Round 1: 📐Geometric Stealth Shell

Design Decisions That Shape the Shell

▪️ Faceted polygonal surfaces replacing traditional curved cabin

We’re not doing curves. Curves bounce radar straight back. Inspired by stealth aircraft logic, we’ve replaced soft transitions with sharp, angular polygonal planes that deflect radar waves in multiple directions. The result? A low Radar Cross Section (RCS) without the need to rely solely on absorbent coatings.

▪️ Roof sloped backwards at 25°

Tilting the roof backwards does more than just look aggressive, it breaks direct radar reflections and assists with water runoff in open-sea conditions. Bonus: this slant improves rear-view visibility from inside the cabin.

▪️ Side walls tilted outward at 20°

This one’s a stealth and space move. By angling the side panels outward, we reduce the number of perpendicular surfaces that bounce radar directly back. At the same time, we gain a bit of extra elbow room where agents need it most: at shoulder height.

▪️ Front windshield at compound angle for radar deflection + visual field

The windshield is one of the most critical zones, both functionally and in terms of RCS. Ours uses a compound angle that supports two things: deflecting radar off-axis and maximizing field of vision for the pilot and tactical shooter. It’s stealth + usability in one.

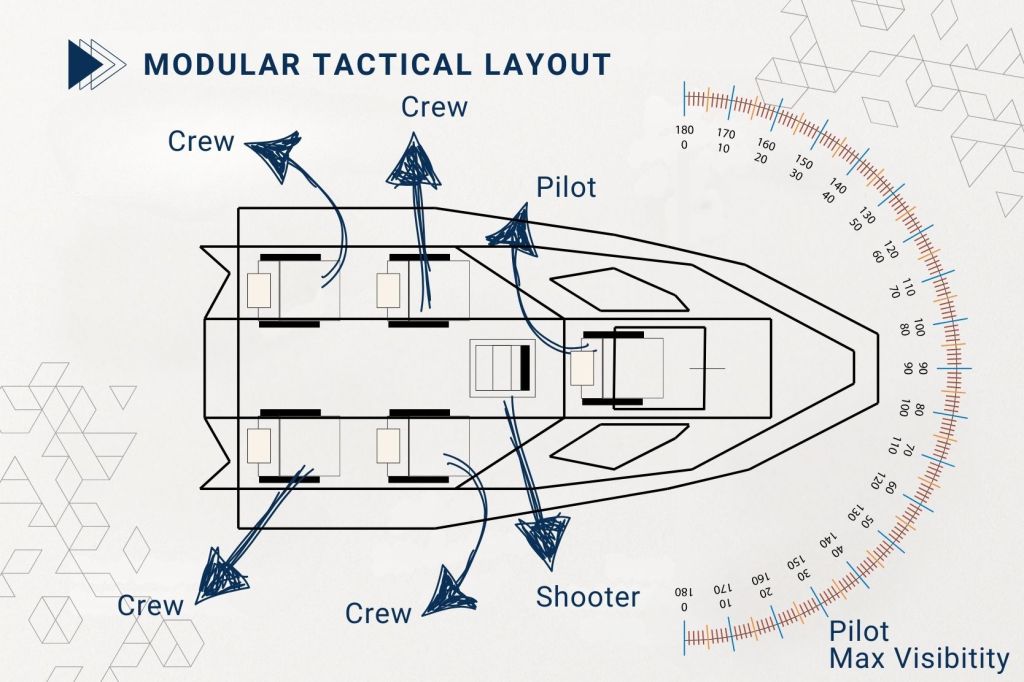

Round 2: 🧩Modular Tactical Layout

Designing a stealth shell is only half the story, the other half is what happens inside.

This layout was built from the ground up for tactical readiness and comfort under pressure. Every inch counts when you’re fitting 6 federal agents, their gear, and mission-critical tech inside a compact armored cabin. Here’s what we engineered:

- Top hatch aligned with shooter seats: Agents can rapidly access the roof opening without crowding or crossflow. The placement was refined through spatial testing using full-scale mockups.

- Pilot seat with max visibility: The driving position isn’t just ergonomic — it’s surgically aligned with the forward cone of visibility, minimizing blind spots and cognitive switching during maneuvers.

- Six internal shock-absorbing seats: Each seat is mounted on a recoil-dampening base and spaced for fast deployment. No one is buried behind gear or squeezed into blind corners.

- Wall thickness optimized for NEB III layering: We calculated internal dimensions around ballistic panel tolerances to ensure full protection without sacrificing interior mobility.

This isn’t a layout for luxury. It’s built for mission execution under high stress, high speed, and hostile threat environments.

🔫Rooftop Weapon Mount — Co-developed with Nautos

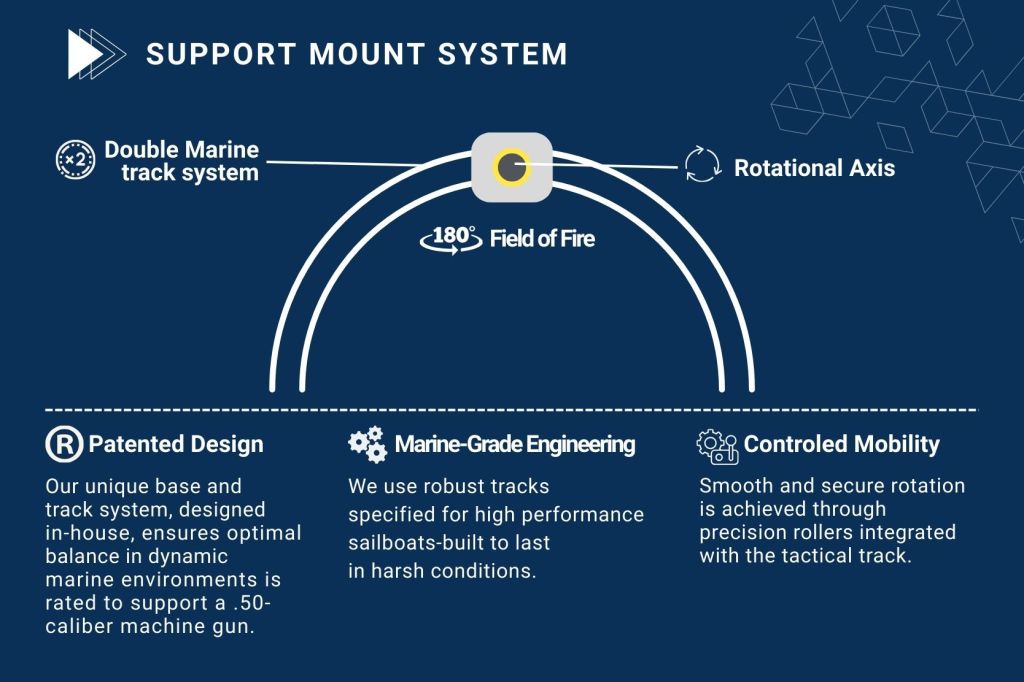

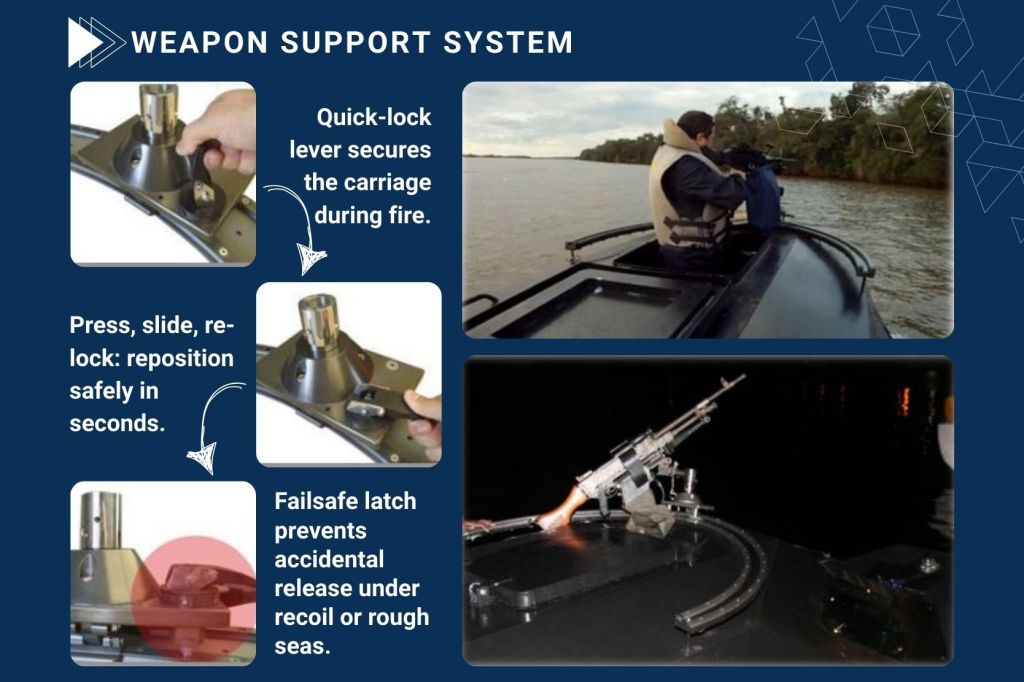

One of the standout features of the DGS 888 Pegasus is our custom-designed and patented rooftop machine gun mount , a solution engineered entirely in-house, Co-developed with NAUTOS to meet the operational realities of federal police agents in high-stakes environments. the mount was engineered from the ground up using marine-certified hardware

We’ve achieved a 180° field of fire through a precision-aligned overhead rail system that guarantees maximum sweep coverage and fast targeting without compromising safety or stability. The design ensures that the shooter can operate from within the protective perimeter of the armored cabin, drastically reducing exposure.

What makes this system exceptional is the rail structure: we repurposed ultra-resistant nautical-grade tracks, typically used in high-performance sailboats, for tactical use. The result is a mount that is shock-resistant, lightweight, and built for saltwater endurance — with virtually zero flex or misalignment, even under recoil. It’s not just rugged — it’s smartly engineered to minimize maintenance and maximize uptime.

Internally, we implemented reinforced roller-based bearings, allowing smooth rotation and adjustable tension. This is not an off-the-shelf solution — it’s a fully engineered, field-ready innovation, developed by our team and protected under patent for exclusive tactical use.

This weapon support system wasn’t an afterthought, it was baked into the core layout of the boat from day one. It respects the cabin’s stealth geometry, does not interfere with radar angles, and ensures that every action, from patrol to pursuit, can be backed by immediate firepower when needed.

🛡️Ballistic Armor System — in partnership with BCA Ballistic Protection

The entire structure is protected with NEB Level 3 ballistic shielding, capable of resisting .30 and .60 caliber rounds, delivering reliable protection in active combat zones. To engineer this, DGS and BCA Ballistic Protection co-developed the armor architecture for both the stealth cabin and the fuel tanks.

- Seamless “survivability capsule.” The faceted stealth geometry created potential weak points at panel junctions. We solved this with interlocking ballistic metal splice plates and overlapping seams along every joint—forming a continuous armored shell with no line-of-fire gaps.

- Ultra-light naval panels. BCA supplied UHMWPE ballistic solutions tailored for marine use—lowest weight and thickness in the international market and stable under humidity and UV, preserving their original physical/chemical properties.

- Fuel-tank protection. The three fuel tanks are wrapped with NEB Level 3 armor, integrating with the cabin capsule to protect critical systems and maintain buoyancy.

- Proven & documented. The result became a BCA case study, now part of their portfolio, and a cornerstone of the Pegasus’ mission-ready safety story.

🏗️Cabin-Hull Integration: Efficient Use of Every Millimeter

One of the key design breakthroughs on the DGS 888 Pegasus was how we integrated the cabin structure into the hull without compromising stealth or usability. Instead of simply placing a cabin “on top” of the boat, we carved it into the geometry, letting it flow naturally with the polygonal shell.

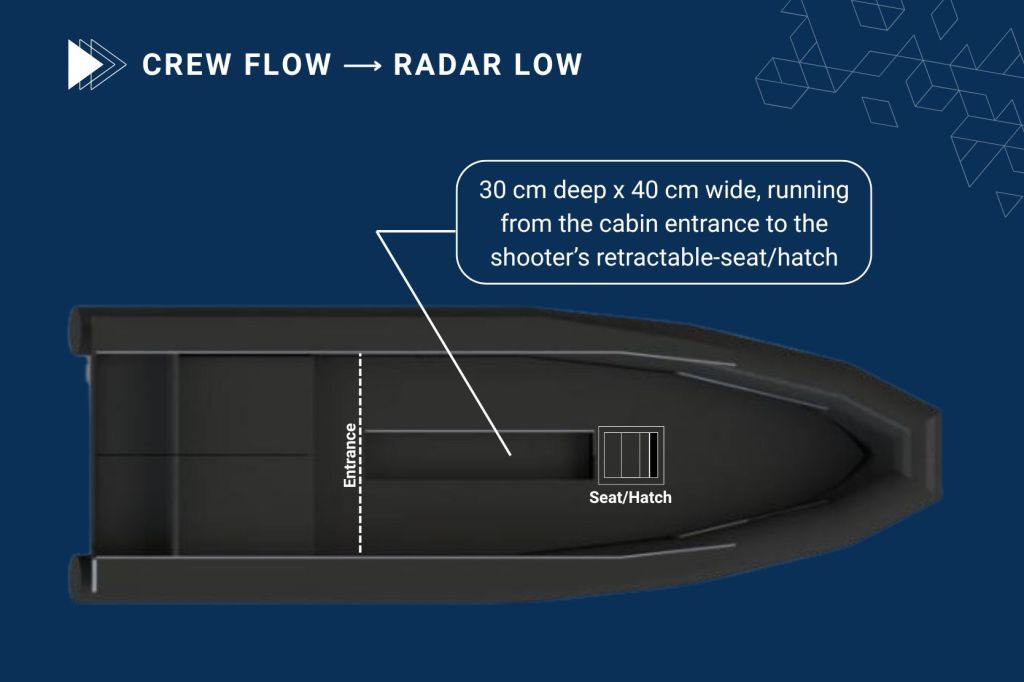

To keep the interceptor’s profile stealth-low without squeezing the crew, we carved a recessed corridor into the deck under the cabin footprint — 30 cm deep x 40 cm wide, running from the cabin entrance to the shooter’s retractable-seat/hatch. This lets us lower the external cabin by 30 cm (reducing visual and radar signature) while preserving standing headroom and a clear, shoulder-free path for geared agents to move, reload, and swap roles fast. The lowered shell also improves stability/center of gravity and keeps the armored capsule intact—stealth on the outside, human-centered usability on the inside.

From the technical side, the hull measures 8880 mm in length and 2835 mm in beam, with a deck-to-roof height of 1550 mm, allowing us to maximize interior cabin volume while keeping the exterior compact and angular.

The cabin itself spans roughly 4940 mm, giving us a usable envelope to organize 6 tactical seats, a driver with a wide visibility cone, and rear equipment storage — all within a stealth-friendly shape. Thanks to the angled walls and optimized thickness for NEB III armor, we didn’t have to sacrifice interior layout for protection.

With a deck width of 1500 mm aft and carefully sloped side panels, we maintained walkable access along key operational zones, without creating flat vertical surfaces that would reflect radar.

This part of the project is where UX design and tactical engineering really started speaking the same language. Every surface, seat, and corner was mapped with both human ergonomics and stealth performance in mind.

📡Navigation & Mission Equipment

On river patrols at the triple border, agents described the same pain points over and over: darkness, cluttered channels, sudden shallows and debris, engine uncertainty, noise that drowns out voice commands, and the constant pressure to decide fast with limited visibility. We sat in on nighttime runs, interviewed crews after missions, and mapped tasks at the helm. The result wasn’t a shopping list of gadgets, it was a set of tools built to answer specific operational needs:

Everything here ladders back to situational awareness, reduced cognitive load, and safer, faster decisions. It’s not gear for gear’s sake; it’s the minimum, integrated set that lets a small crew operate confidently in the dark, in current, and under pressure.

🎯What we chose and why it matters

Raymarine 14.1” Multifunction Display (E-Series)

What it is: A large, sunlight-readable MFD that fuses radar + chartplotter + sonar on a single screen.

Why this brand: Raymarine’s marine UI is fast, clean, and stable; menu depth is predictable and Night Mode is genuinely usable.

Impact: Fewer head-down moments. Operators keep eyes up while flicking between layers (radar/plotter/sonar) without context switching. It reduces cognitive load during high-speed maneuvers.

Raymarine HD Digital Radome

What it is: A compact radar dome with long-range awareness in bad weather and at night.

Why this brand: Reliable target tracking and clutter reduction; easy network integration with the MFD.

Impact: Earlier detections = earlier decisions. Agents asked to “see threats before they see us”; this delivers that, without adding extra displays or workflows.

FLIR Thermal Camera

What it is: Thermal vision for night and low-visibility patrols.

Why this brand: FLIR’s marine lineup is robust, with stable image processing and clear heat signatures that matter on rivers.

Impact: Detects people, boats, logs, and shoreline movement when the human eye can’t. It’s the difference between guessing and knowing where to steer.

Thru-Hull Depth Sensor

What it is: A real-time depth transducer mounted through the hull.

Why we chose it: Accurate bottom reading is non-negotiable in shallow, debris-prone rivers.

Impact: Prevents sudden groundings and prop damage; lets the pilot anticipate instead of react.

ICON Digital Navigation + GPS + Digital Odometer

What it is: The navigation backbone (speed, position, trip), paired with the GPS receiver and a simple odometer for distance tracking.

Why we chose it: Familiar, no-nonsense feedback for the helm—what crews already trust.

Impact: Gives the pilot a stable mental model of where we are and how fast we’re closing—with no extra screen gymnastics.

Electronic Engine-Monitoring System

What it is: Real-time engine health (temps, pressures, alarms).

Why we chose it: Predictable alerts and a clean signal path to the MFD/helm instruments.

Impact: Fewer surprises. Prioritized warnings keep the pilot focused; crews can make clear go/no-go calls under stress.

360°Remote-Controlled Searchlight

What it is: A 360° motorized spotlight you control from the helm.

Why we chose it: Hands-on-wheel, eyes-on-water; no one needs to step outside to scan banks and channels.

Impact: Instant situational sweep at night without breaking formation or exposing crew.

2 Auxiliary Headlights

What it is: Fixed forward beams to boost near-field visibility.

Why we chose it: Simple, bright, reliable; complements the searchlight.

Impact: Reduces pilot strain and makes close-range obstacles obvious at speed.

Anchorlift Windlass

What it is: A powered windlass for anchor deployment/retrieval.

Why this brand: Marine-proven durability and straightforward controls.

Impact: Fast, safe anchoring during boardings or emergency stops; less manual handling in rough conditions.

Loud-Hailer + Siren

What it is: A voice projection + warning system.

Why this brand: Local service network and strong output clarity (important on noisy, fast-flowing rivers).

Impact: Clear command & control at distance when engine and current drown normal voice—exactly what operators asked for.

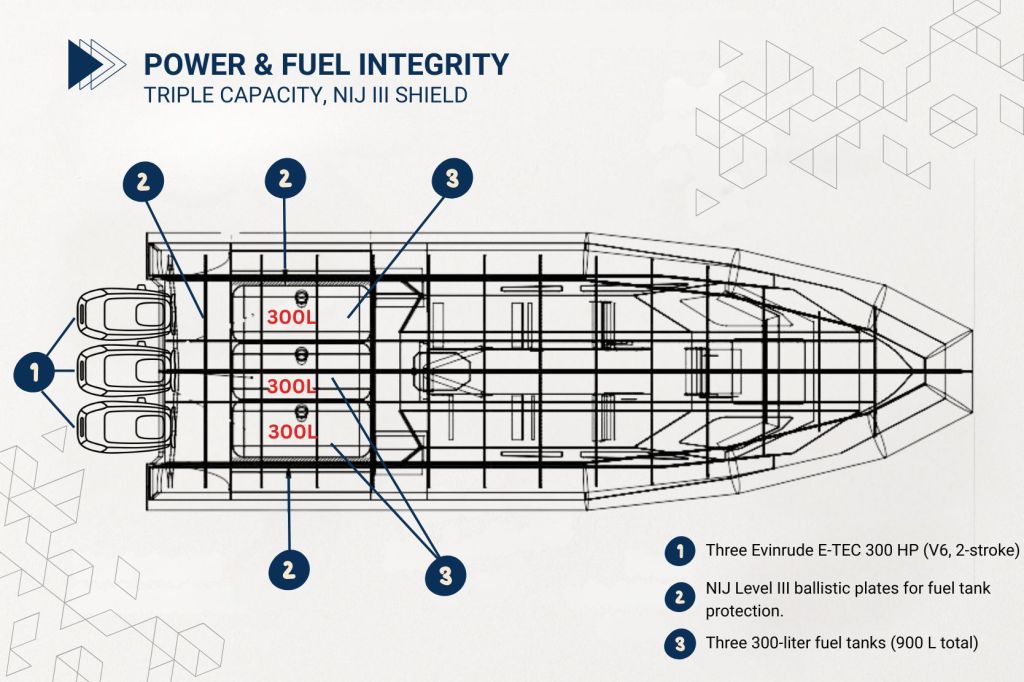

🔋Power & Range — built for border missions

For Pegasus we chose a triple-outboard setup: three Evinrude E-TEC 300 HP (V6, 2-stroke)—900 HP total—paired with three 300-liter fuel tanks (900 L total). This package gives the boat a 30-kn cruise and 45-kn top speed, with ~5 hours / ~150 nm of operational autonomy. It’s not just about going fast; it’s about delivering predictable, mission-ready performance when agents need it most.

Why this configuration

- Instant thrust, fast planing: The E-TEC’s direct-injection 2-stroke profile delivers quick hole-shot and responsive throttle, critical for intercepts, evasive maneuvers, and fighting current on narrow rivers.

- Redundancy that protects the mission: Three engines mean fault tolerance: if one unit is compromised, the vessel can still return or continue under reduced power.

- Endurance without guesswork: 900 L across three independent tanks provides ~150 nm of range at cruise, reducing refuel stops and allowing longer patrol windows.

- Balance and control. Staged fuel use across three tanks helps maintain trim and handling as the mission progresses.

What this gives operators on the Brazil–Paraguay–Argentina border

- Faster interdictions and safer standoff: reach, hold, and break contact at will.

- Reliable pursuit in shallow, debris-prone channels without sacrificing acceleration or steering authority.

- Lower cognitive load at the helm: predictable cruise speed and range planning let crews focus on the target and environment. Not on fuel math.

- Resilience under stress: power, autonomy, and backup built in, so the mission—not the machinery—sets the limits.

✅ Conclusions — DGS 888 Pegasus

The Pegasus wasn’t just a boat build; it was a multi-disciplinary program that blended stealth science, naval engineering, and field-driven UX. Grounded in interviews with Brazil’s border agents, we translated mission pain points into a patented, combat-ready platform that is fast, quiet, hard to detect—and humane to operate.

What we built on

- Research stack: desk research, cross-domain benchmarking (air & naval stealth), and two rounds of qualitative interviews with full tactical teams (Alpha & Beta).

- Specialist partners: Nautos (marine-grade, 180° rooftop weapon mount using sailboat-class tracks) and BCA Ballistic Protection (pioneering naval armor system for cabin + fuel tanks).

Key design outcomes

- Stealth-by-shape: faceted cabin, sloped roof/walls, optimized glazing → reduced RCS without losing sightlines.

- Survivability capsule: NEB Level III with UHMWPE panels + ballistic steel joiners closing angular weak points—forming a true crew capsule.

- Weapon ergonomics: patented rooftop mount + retractable shooter seat + quick hatch for wide, stable traverse.

- Crew-first interior: modular 6-seat layout with shock-mitigating chairs and a 30-cm dropped-deck corridor (40-cm wide) to keep the cabin low while improving mobility.

- Propulsion & range: triple Evinrude E-TEC 300 hp (900 hp total), 900 L fuel (≈ 5 h / 150 nm).

- Mission systems: fused radar/GPS/sonar display, thermal imaging + remote searchlight, depth sensor, engine health monitoring, powered windlass, loud-hailer.

Why it matters

- UX under fire: lower cognitive load, faster transitions (navigate ↔ engage), safer posture for long, bumpy river ops.

- Operational effect: stealthier approach, quicker interdictions, fewer maintenance burdens.

- Pioneering & IP: a patented Brazilian solution born from cross-industry know-how and rigorous field validation.

💥Impact

- Visibility & credibility: Featured in leading national media and international defense press, positioning DGS as a Brazilian reference in stealth riverine craft.

- Commercial outcomes: New procurement cycles and repeat contracts fueled by the project’s performance in the field.

- Strategic alliances: Expanded network of technical partners (marine mounts, ballistic systems), accelerating innovation and delivery.

- Category leadership: Consolidated DGS’s status as an HDPE pioneer, blending survivability, low RCS, and human-centered design.

📰Press & recognition

The project gained strong coverage in national media and international naval/defense outlets, reinforcing its relevance beyond the design community.

In short: DGS 888 Pegasus set a new bar for tactical riverine operations in Brazil by uniting stealth geometry, survivability, and genuinely user-centered design.